How to Dampen Sound in a Large Room

Large rooms — whether offices, restaurants, studios, or open-plan homes — often face one common problem: poor acoustics. Sound bounces off hard surfaces, creating echoes, reverberation, and unwanted noise. If you’ve ever struggled to hold a conversation in a spacious hall or noticed unclear audio in a big meeting room, you’ve experienced this issue firsthand.

In this article, we’ll explore how to effectively dampen sound in a large room, and how Guangdong Leeyin Acoustics, a global leader in wood slat acoustic panels, provides high-performance, visually appealing acoustic solutions for any space.

Understanding Sound Dampening

Before jumping into solutions, it’s important to understand what “sound dampening” means.

-

Sound dampening focuses on reducing echo and reverberation within a room.

-

It doesn’t block sound from entering or leaving (that’s soundproofing), but instead improves sound clarity and speech intelligibility.

In large spaces with hard floors, tall ceilings, and bare walls, sound waves reflect freely — amplifying noise. The key to solving this is adding soft, porous, or textured materials that absorb sound energy instead of reflecting it.

1. Use Acoustic Wall Panels

One of the most effective ways to dampen sound in a large room is by installing acoustic wall panels. These panels absorb mid to high frequencies, reducing echoes and improving overall room acoustics.

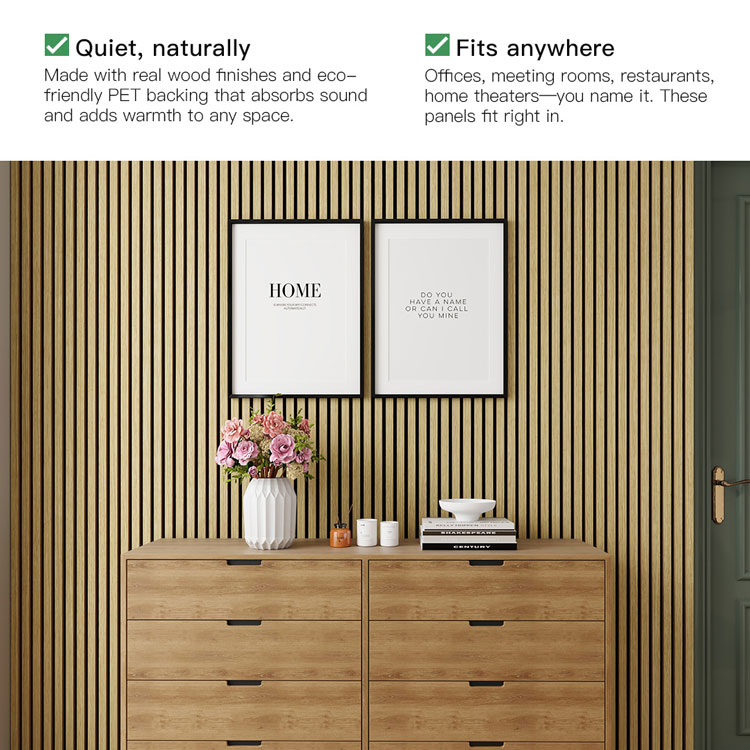

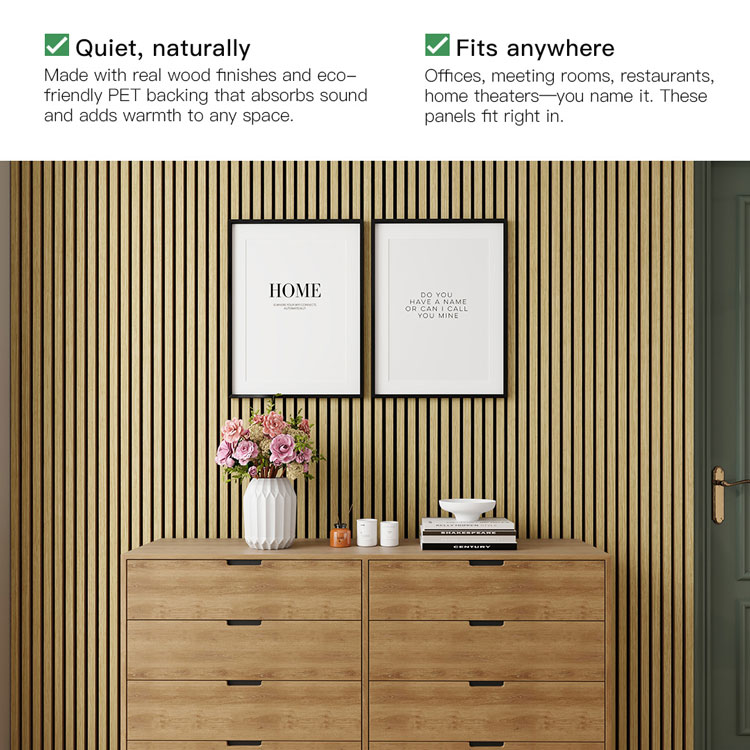

✅ Best Choice: Leeyin Wood Slat Acoustic Panels

At Guangdong Leeyin Acoustics, we specialize in wood slat acoustic panels — a perfect blend of modern design and high acoustic performance.

Each panel features natural wood veneer slats on a recycled PET felt backing, which efficiently absorbs unwanted sound waves.

Benefits of Leeyin acoustic panels:

-

High sound absorption coefficient (NRC up to 0.9)

-

Elegant wood finish for modern interiors

-

Easy installation on walls and ceilings

-

Eco-friendly materials meeting international standards

Whether you’re designing a restaurant, office, auditorium, or living room, Leeyin panels transform acoustics and aesthetics simultaneously.

2. Add Acoustic Ceiling Treatments

Sound doesn’t just bounce off walls — ceilings play a big role too, especially in large rooms with hard or reflective surfaces.

✅ Solutions:

-

Install acoustic ceiling panels or baffles to absorb sound waves from above.

-

Use suspended acoustic clouds in large commercial or public spaces for stylish noise reduction.

Leeyin offers a wide range of acoustic ceiling panels designed for both functionality and visual appeal, making them ideal for open offices, classrooms, and conference halls.

3. Cover the Floor with Soft Materials

Hard flooring such as tiles or hardwood reflects sound, contributing to echo. To counter this, incorporate soft, absorbent flooring materials.

✅ Try:

-

Carpets or large rugs in key areas.

-

Acoustic underlays beneath floors to reduce impact noise.

-

Fabric mats in open spaces for both comfort and sound absorption.

These simple changes can make a noticeable difference, especially in spaces like hotel lobbies or living rooms.

4. Use Curtains, Drapes, and Upholstered Furniture

Soft furnishings naturally help dampen sound. Heavy curtains, upholstered furniture, and fabric décor elements break up reflective surfaces and add warmth to your space.

✅ Tip:

Choose thick, multi-layer curtains for windows or glass partitions — these are among the most reflective surfaces in large rooms. Combining them with Leeyin acoustic panels provides a balanced acoustic solution that’s both functional and stylish.

5. Treat Corners and Open Areas

In large rooms, corners often act as sound traps, where low-frequency noise builds up. Adding bass traps or corner panels can help smooth out these acoustic imbalances.

If your space has open areas or high ceilings, use freestanding acoustic dividers to break up the sound path. Leeyin offers customizable acoustic screens and panels perfect for flexible room layouts.

6. Combine Design with Performance

The best acoustic solutions are both functional and beautiful. Modern architecture demands designs that enhance spaces visually — and that’s exactly what Leeyin’s wood slat acoustic panels deliver.

Available in a wide range of finishes such as Natural Oak, Walnut, Teak, and Black Ash, Leeyin panels fit seamlessly into contemporary interiors while maintaining excellent sound absorption.