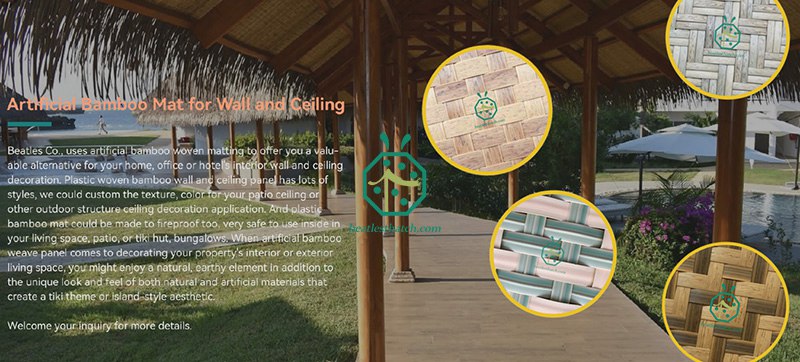

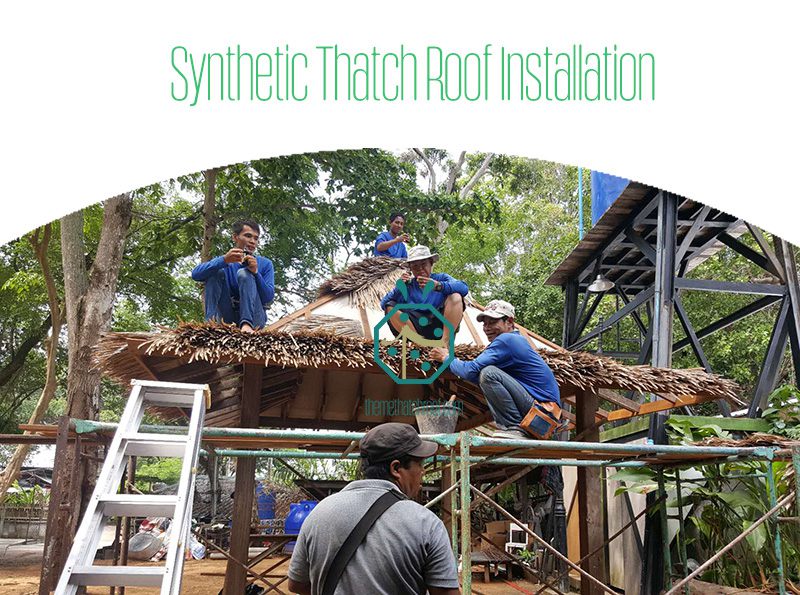

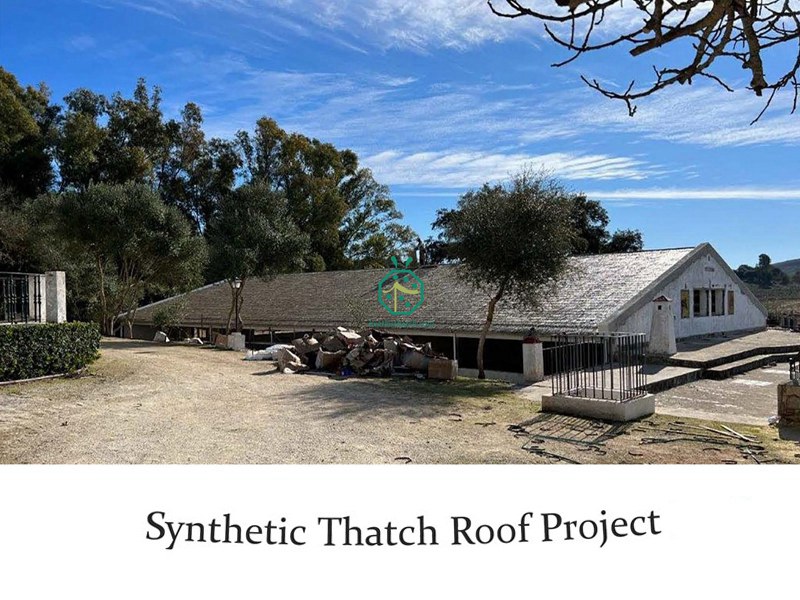

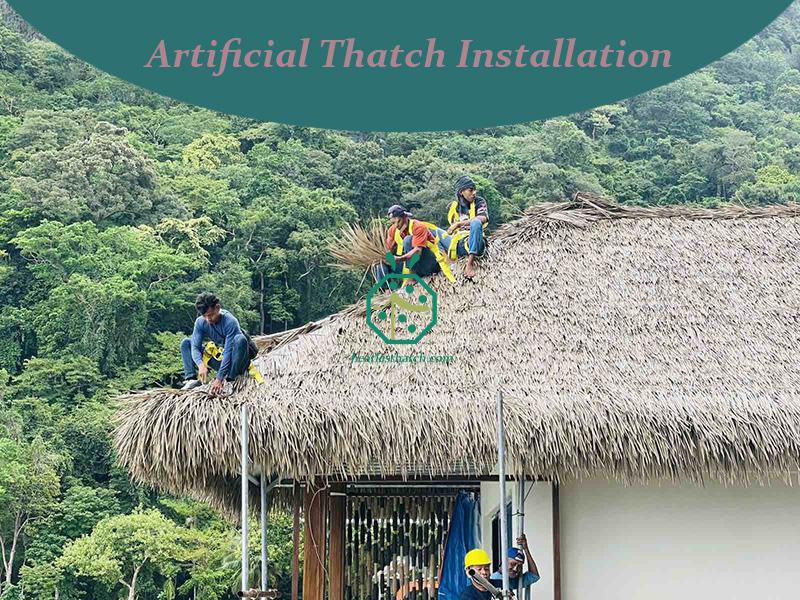

Synthetic thatch is an innovative roofing material designed to simulate the appearance of traditional bamboo thatch roofs or palm thatch roof or other types of natural thatch materials while offering numerous benefits for both residential and commercial applications. With its realistic bamboo-like texture and natural-looking color variations, synthetic thatch provides an authentic and charming aesthetic that instantly enhances the tropical or exotic ambiance of any property. It captures the essence of traditional bamboo thatch roofs, creating a visually appealing and inviting atmosphere. Due to the above benefits, various resort hotels are using synthetic thatch for their outdoor buildings' roofing decoration.

Benefits of Synthetic Thatch Roof for Resort Hotel

Using synthetic grass thatch for a beach resort can offer several advantages. Here are some reasons why it can be a good choice:

1. Durability:

Synthetic grass thatch is designed to be highly durable and resistant to harsh weather conditions, including exposure to sunlight, saltwater, and sand. It can withstand the coastal environment without deteriorating or fading over time.

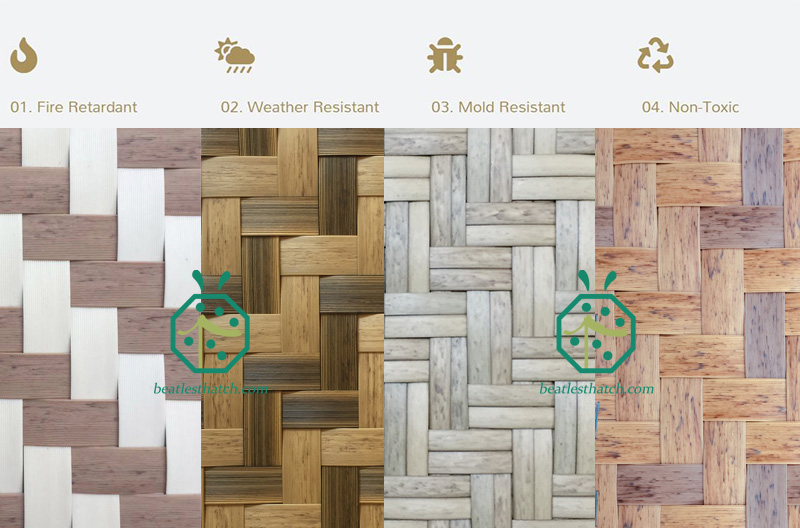

2. Fire Safety:

Synthetic grass thatch is often treated with fire-retardant materials, making it a safer option compared to natural thatch roofs. It reduces the risk of fire hazards from beach bonfires, cooking activities, or accidental sparks.

3. Cost-effectiveness:

Synthetic grass thatch is generally more cost-effective than natural thatch in the long run. It requires minimal maintenance, doesn't need regular replacement or repair, and can offer significant savings on maintenance costs over time.

4. Sustainability:

Natural thatch roofs may contribute to deforestation or habitat disruption, whereas synthetic grass thatch is an environmentally friendly alternative. It doesn't require harvesting and doesn't impact natural ecosystems, making it a sustainable choice for beach resorts committed to eco-friendly practices.

5. Versatility:

Synthetic grass thatch can be produced in different colors and styles, allowing you to customize the appearance of your beach resort. You can choose a color that complements the beach surroundings or opt for a more vibrant look to create a unique aesthetic.

6. Low Maintenance:

Synthetic grass thatch requires minimal upkeep compared to natural thatch. It doesn't attract pests, doesn't need to be replaced regularly, and can be easily cleaned with water or gentle sweeping. This saves time and effort for resort staff, allowing them to focus on other important tasks.

7. Enhanced Ambiance:

Synthetic grass thatch roofs offer a tropical, beach-themed ambiance that can enhance the overall guest experience at a beach resort. It creates an atmosphere of relaxation, tranquility, and tropical escape, adding to the appeal and charm of your resort.

8. Longevity:

Synthetic grass thatch has a longer lifespan compared to natural thatch. It doesn't degrade due to weather exposure or biological decay, ensuring a longer-lasting and aesthetically pleasing roof covering for your beach resort.

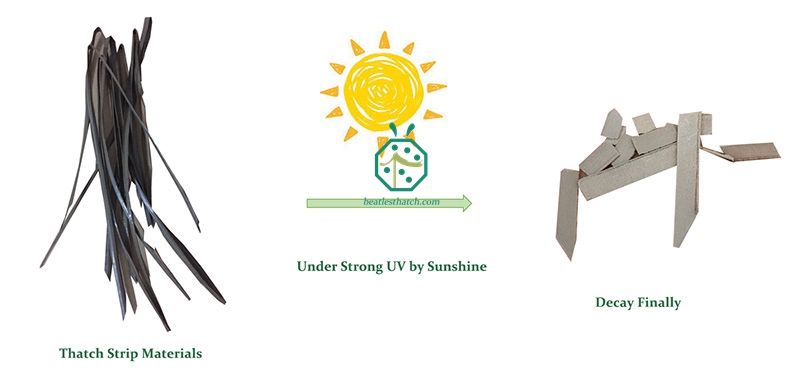

How to Judge the Quality of Synthetic Thatch Roof

In the market, there lots of synthetic thatch roof manufacturers, some companies have longer history and some companies only produce synthetic thatch roof for short time. Even though synthetic thatch roof seems a simple plastic product that does not need many technologies threshold, every type of plastic thatch products will have great performance of the quality for outdoor use. But actually, not every type of plastic types are working well in different environments, different plastic materials have different chemical characteristics, which are suitable for different environment. At the same time, different plastic materials need different types of additives for UV retardant or antioxidant purpose. Thus, many synthetic thatch roof products' quality is actually chaos in the market. So, how could we judge the quality of synthetic thatch roof tiles? We could consider the following factors:

1. Material Quality:

Examine the materials used in the synthetic thatch. High-quality synthetic thatch is typically made from durable and UV-resistant materials that can withstand exposure to sunlight without fading or degrading over time. Look for products that are specifically designed for outdoor use and can withstand the weather conditions of your area.

2. Realistic Appearance:

Assess the authenticity of the synthetic thatch's appearance. The best quality synthetic thatch has a realistic texture and color that closely resembles natural thatch. Look for variations in color, texture, and shape, similar to what you would find in real thatch. It should closely mimic the aesthetic qualities of natural materials.

3. Fire Resistance:

Check if the synthetic thatch has been treated with fire-retardant materials. Fire safety is crucial, especially for roof coverings. Ensure that the product meets the required fire safety standards and regulations to minimize fire hazards.

4. Durability and Longevity:

Consider the durability and lifespan of the synthetic thatch. A high-quality product should be designed to withstand the elements, including wind, rain, and temperature fluctuations, without deteriorating or requiring frequent replacement. Look for warranties or guarantees provided by the manufacturer as an indicator of their confidence in the product's longevity.

5. Certifications and Testing:

Look for any relevant certifications or testing that the synthetic thatch has undergone. Products that have been tested and certified by reputable organizations or industry standards can provide assurance of their quality and performance.

6. Customer Reviews and Reputation:

Research customer reviews and testimonials about the synthetic thatch product or the manufacturer. Feedback from other customers can offer insights into the product's quality, durability, and customer satisfaction. Additionally, establish the reputation of the manufacturer or supplier by considering their experience in the industry and their track record of delivering quality products.

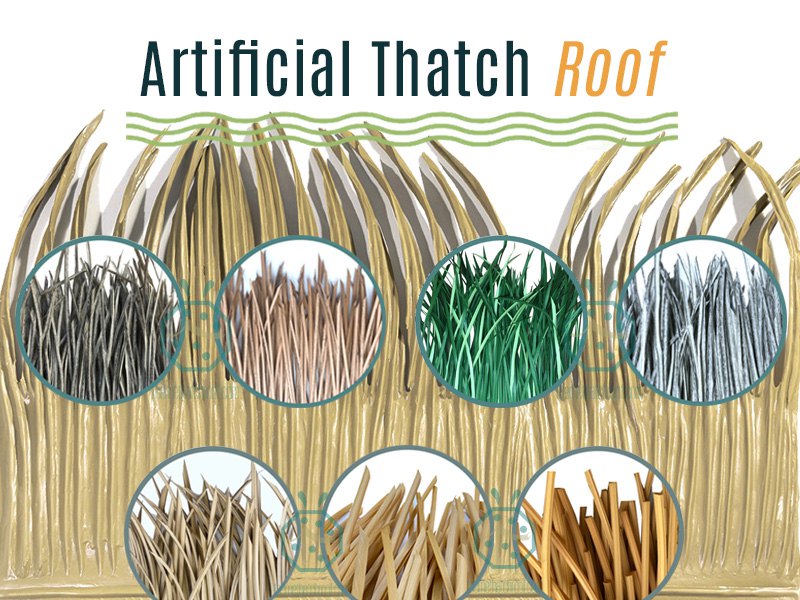

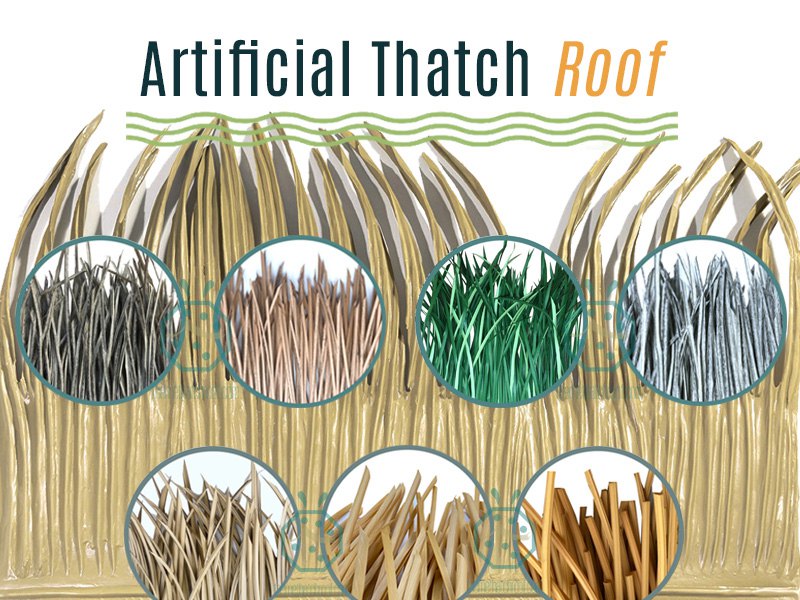

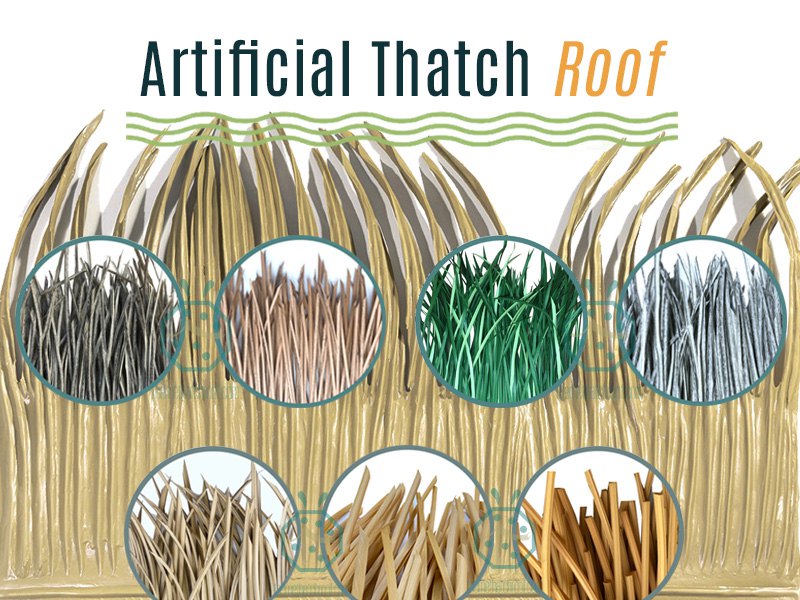

How Many Types of Synthetic Thatch Roof Tiles

Synthetic thatch roofs are available in various types, each simulating the appearance of different natural thatch materials. These are just a few examples of the types of synthetic thatch roofs available based on their simulated appearance. Each type offers its unique visual appeal and can be chosen based on the desired style and ambiance of the project and offers a wide variety of options for achieving different architectural styles and cultural aesthetics. Here are some common types of synthetic thatch roofs based on their simulated look:

1. Straw Thatch:

Synthetic straw thatch replicates the texture and color of natural straw roofing. It features a golden or light brown color and a fibrous appearance, mimicking the charm and rustic appeal of traditional straw thatch roofs.

2. Palm Thatch:

Synthetic palm thatch emulates the look of natural palm thatch roofs commonly seen in tropical regions. It captures the unique texture and layered structure of palm leaves, offering a realistic alternative that complements a tropical or exotic aesthetic.

3. Reed Thatch:

Synthetic reed thatch imitates the appearance of natural reed thatching, which is often found in regions with wetlands and marshy areas. It features a light tan to golden color, with long and slender fibers that recreate the rustic and earthy charm of traditional reed roofs.

4. Bamboo Thatch:

Synthetic bamboo thatch is designed to simulate the elegance of traditional bamboo roofs. The synthetic material captures the texture, color variations, and shape of bamboo, offering a durable and long-lasting alternative to natural bamboo thatching.

5. Alang Alang Thatch:

Synthetic alang alang thatch reproduces the look of roofs made from alang-alang grass, which is commonly used in Southeast Asian architecture. It features a light golden color with a rough and textured surface, giving a traditional and exotic look.

6. Coconut Thatch:

Synthetic coconut thatch replicates the appearance of roofs made from coconut leaves. It typically features a layered, textured surface with a light to medium green color, mirroring the tropical aesthetics of traditional coconut thatch roofs.

7. Raffia Thatch:

Synthetic raffia thatch imitates the look of raffia palm leaves and their characteristic long, thin fibers. It usually has a light tan or golden color and provides a natural and rustic appearance.

8. Nipa Palm Thatch:

Synthetic nipa palm thatch recreates the look of roofs made from nipa palm leaves. It captures the unique texture and arrangement of palm fronds, often featuring a light green color. Nipa palm thatch is commonly used in coastal areas and provides a coastal or beach-inspired ambiance.

9. Attap Thatch:

Synthetic attap thatch mimics the appearance of attap roofs, which are traditionally constructed from leaves of the Nypa fruticans palm. It showcases a layered structure with shades of brown and green, evoking a tropical and rustic feel.

How to Choose Synthetic Thatch Roof Types to Design Your Resort Hotel

There are lots of resort hotels around the world. Some are near the beach, some are on the mountain, some are close to desert, some are near the waterfront theme park, some are near the zoo. Every place has different landscape. There are so many types of synthetic thatch roof, different thatch roof has different looking too. How to design the thatch roof buildings and how to choose the synthetic thatch roof according to the location of the resort hotel? Designing thatch roof buildings and selecting the appropriate synthetic thatch roof can be tailored to the specific location and landscape of a resort hotel. Here are some considerations and suggestions to guide the design process:

1. Incorporate Local Materials and Cultural Elements:

To create an authentic sense of place, consider incorporating local materials and cultural elements into the design. Research traditional roofing styles and architectural features of the region to inspire the design of the thatch roof structures.

2. Consider the Surrounding Landscape:

Take into account the natural surroundings and landscape features of the resort hotel. If it's near the beach, consider a thatch roof design that complements the coastal setting. For mountainous areas, a rustic and organic-looking thatch roof may blend well with the surrounding scenery.

3. Choose Colors and Decorative Accents:

Select colors and decorative accents that complement the overall theme and atmosphere of the resort hotel. For example, in waterfront theme parks, vibrant and tropical colors could be incorporated into the synthetic thatch roof to create a lively and fun ambiance.

4. Balance Aesthetics and Practicality:

While aesthetics are important, it's crucial to balance them with practical considerations. Ensure that the chosen synthetic thatch roof material is suitable for the climate and environment of the location. Consider factors like wind resistance, durability, and fire safety when making the selection.

5. Seek Professional Advice:

Consult with architects, designers, or thatch roof specialists who have experience working with synthetic thatch roofs in various environments. They can provide valuable insights and recommendations based on their expertise.

6. Create a Complementary Atmosphere:

Aim to create a harmonious atmosphere between the thatch roof buildings and the surrounding area. Pay attention to other architectural and landscaping elements such as building materials, colors, textures, and plantings to ensure a cohesive and visually appealing overall design.

By considering these factors, resort hotels can design thatch roof buildings that blend seamlessly with their location and provide a unique and immersive experience for guests. The choice of synthetic thatch roof can be tailored to match the specific landscape and desired aesthetic of each hotel's surroundings.