Colored sand floor coatings offer a wide variety of colors, allowing for customization based on specific needs. They are categorized as follows:

1. Basic Colors

Monochromatic Colors

Common Industrial Colors: Dark Gray, Dark Blue (Stain-Resistant and Wear-Resistant)

Commercial/Home Colors: Light Yellow, Beige, Sky Blue (Creating a Warm Atmosphere)

Specialty Colors: Green (Hospitals, Kindergartens), Vivid Red (Warning Areas)

Primary Color Derivatives

By mixing the three primary colors red, yellow, and blue, you can create transitional colors like orange, green, and purple. For example:

Red + Yellow = Orange (Less red and more yellow creates a darker yellow, while adding white creates a lighter yellow). Yellow + Blue = Green (Less yellow, more blue for a darker blue, adding white for a lighter green).

2. Customized Solutions

Stone-like Effect

Using natural colored sand particles, we can simulate marble and granite textures, with hundreds of color combinations.

Functional Zoning Color Matching

Industrial Areas: Dark Gray + Yellow Warning Line (Wear-Resistant and Safety Signage)

Commercial Spaces: Gradient Sky Blue + White (Modern Look)

Brand Color Matching Services

For example, Mapei Epoxy Colored Sand offers professional color matching (additional fee) to match tile colors (e.g., #100 White, #120 Black).

3. Recommended Applications

Color Types Applicable Scenarios Advantages

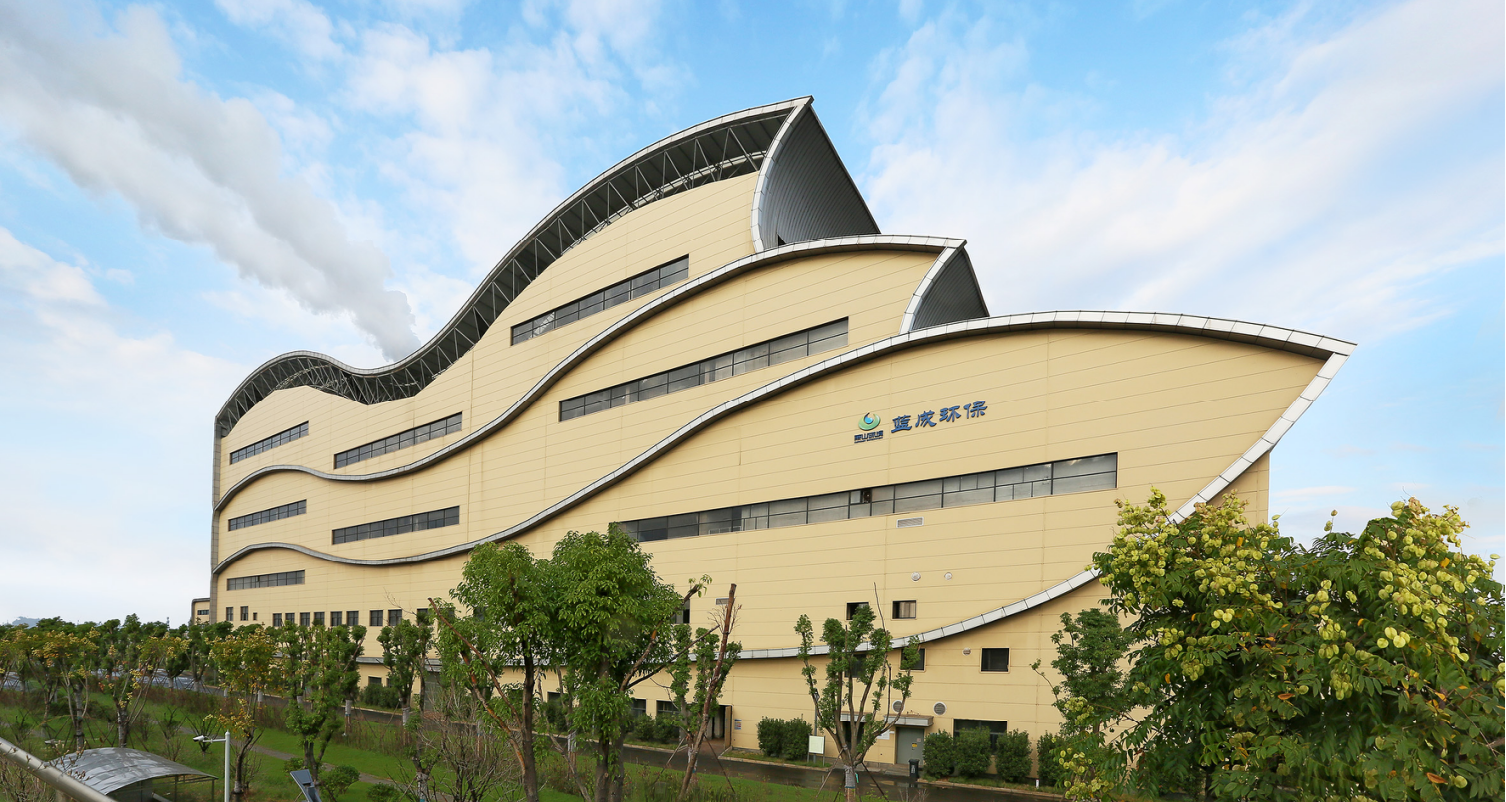

Dark Gray/Dark Blue: Industrial plants and warehouses. Stain-resistant and pressure-resistant.

Light Yellow/Beige: Offices and homes. Brightens the space.

Sky Blue/Green: Hospitals and kindergartens. Soothing and easy to clean.

Multi-Color Parquet: Exhibition halls and shopping malls. Strong decorative effect.

4. Precautions

Lighting Effects: Dark colors are recommended for well-lit areas (to reduce glare), while bright colors are recommended for dark areas (to enhance reflection).

Environmental Performance: Low-VOC, environmentally friendly colored sand (such as Manzhen brand) is preferred.

Application Limitations: On-site color testing is required to confirm the effect and avoid color variations.