If you live in an apartment, a busy neighborhood, or even a two-story house, noise from above can be one of the biggest distractions. Whether it’s footsteps, conversations, or vibrations, many homeowners ask: “Can I soundproof my ceiling?” The answer is yes—and with the right approach, you can significantly reduce noise and improve the comfort of your space.

In this article, we’ll explain how ceiling soundproofing works, cost-effective methods you can use, and why professional acoustic panels—like those from Guangdong Leeyin Acoustics—deliver the best results.

Why Soundproof a Ceiling?

Soundproofing a ceiling helps with:

-

Blocking airborne noise (voices, music, TV sounds).

-

Reducing impact noise (footsteps, furniture movement).

-

Improving overall room acoustics, especially for home offices, studios, and living rooms.

Methods to Soundproof a Ceiling

1. Add Mass to the Ceiling

The heavier the ceiling, the harder it is for sound to pass through. Options include:

-

Adding extra drywall layers.

-

Using Mass Loaded Vinyl (MLV) for effective noise blocking.

-

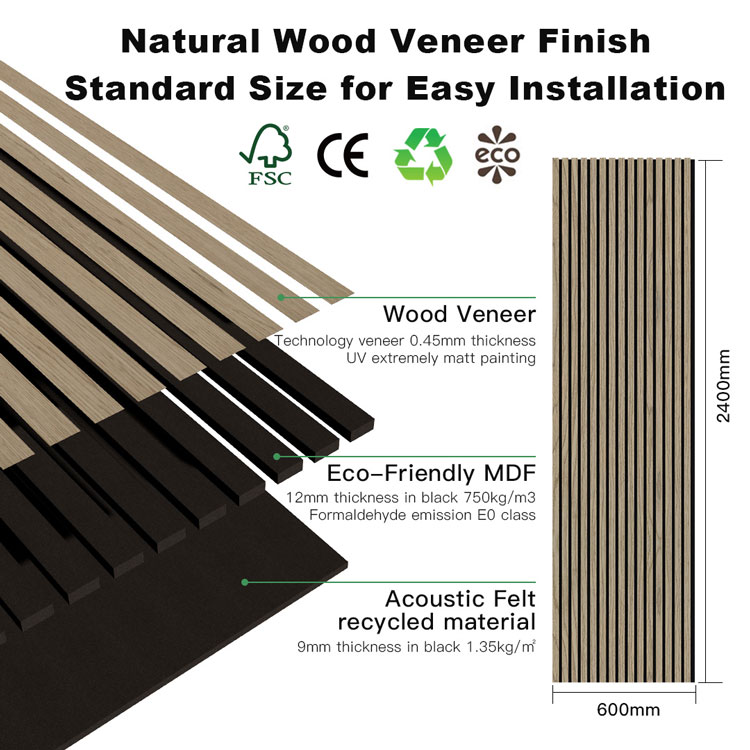

Installing wood slat wall and ceiling panels from Leeyin Acoustics, which combine mass with acoustic absorption.

2. Decouple the Structure

Sound travels easily through solid structures. Decoupling methods such as resilient channels or suspended ceiling systems create a gap that reduces vibration transfer.

3. Use Acoustic Panels

High-quality acoustic panels absorb sound waves, reducing echo and reverberation inside your room. For the ceiling, slat acoustic panels are both functional and visually appealing, making them a popular choice for modern interiors.

4. Seal Gaps and Cracks

Even small gaps allow sound to travel. Use acoustic sealant around ceiling edges, light fixtures, and vents to minimize leakage.

5. Consider Carpeting Above

If possible, adding thick carpets or rugs to the floor above your ceiling provides an extra layer of insulation against impact noise.

Can I DIY Ceiling Soundproofing?

Yes, many soundproofing solutions can be DIY-friendly, such as:

However, for maximum effectiveness—especially in studios or offices—professional-grade solutions like Leeyin Acoustics wooden slat ceiling panels provide both performance and design enhancement.

Why Choose Guangdong Leeyin Acoustics?

At Guangdong Leeyin Acoustics, we are experts in wood slat wall panels and acoustic panels designed for both walls and ceilings.

-

Industry Leader: One of the leading exporters of wood slat wall panels in China.

-

Modern Facility: Over 20,000㎡ advanced factory with high production capacity.

-

Strict Quality Control: Every panel is produced to meet international standards.

-

Eco-Friendly: Our products use E0-grade MDF, PET recycled materials, and FSC-certified wood.

Our solutions are trusted worldwide for soundproofing, acoustic performance, and stylish interior design.