If you own a home studio, whether for music production, podcasting, or video recording, one of your biggest challenges is controlling noise. External sounds can disturb your recordings, while your own audio may leak into other rooms. This is where soundproofing becomes essential. In this article, we’ll guide you on how to soundproof your studio effectively—and how wooden slat acoustic panels can play a key role.

Step 1: Understand the Difference Between Soundproofing and Acoustic Treatment

Before diving in, it’s important to know the difference:

For a studio, you’ll need a combination of both.

Step 2: Seal Gaps and Cracks

Sound travels easily through small openings. Use acoustic caulk, weatherstripping, or door sweeps to seal gaps around doors, windows, and walls. Even a small gap can drastically reduce soundproofing performance.

Step 3: Use Acoustic Panels for Echo Control

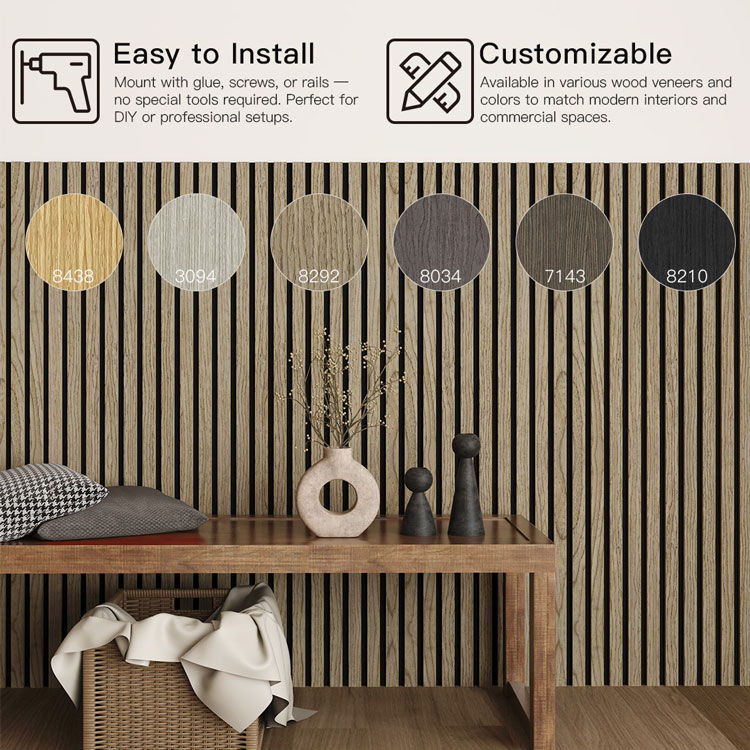

Installing acoustic wall panels is one of the most effective and affordable ways to treat sound in a studio.

-

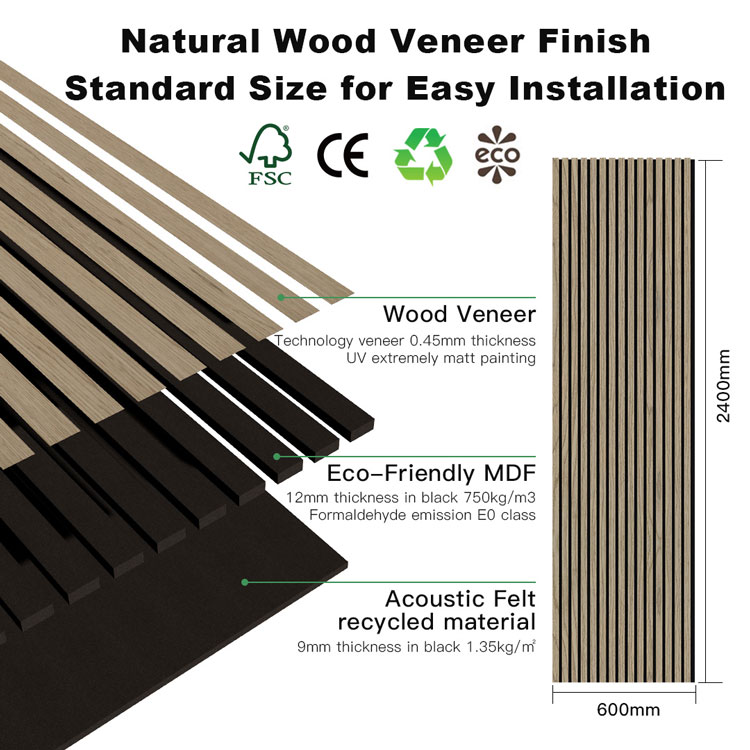

Wooden Slat Acoustic Panels with PET Felt Backing absorb mid-to-high frequencies.

-

Panels reduce echo, flutter, and reverberation, giving you a cleaner recording.

-

Stylish wooden finishes add a modern look while improving functionality.

Step 4: Add Mass to Walls and Ceilings

The more mass your walls have, the less sound can pass through. Consider adding mass-loaded vinyl (MLV) or double layers of drywall for enhanced soundproofing. Pairing these with acoustic panels maximizes performance.

Step 5: Soundproof the Floor

Noise often travels through floors, especially in multi-level buildings. Use carpets, rugs, or acoustic underlay to absorb impact noise.

Step 6: Use Bass Traps for Low Frequencies

Studios often struggle with bass buildup in corners. Installing bass traps (a type of acoustic panel designed for low-frequency absorption) ensures balanced sound across all frequencies.

Why Choose Wooden Slat Acoustic Panels from Guangdong Leeyin Acoustics?

When it comes to professional acoustic solutions, Guangdong Leeyin Acoustics stands out as a trusted manufacturer and exporter.

✅ 20,000 m² modern production facility

✅ Strict quality control aligned with international standards

✅ Specialized in wooden slat acoustic panels with PET felt backing

✅ Sustainable, eco-friendly materials (E0-grade MDF, FSC-certified wood, recycled PET)

✅ Global exports across Europe, North America, and Southeast Asia

✅ OEM/ODM customization to match studio designs

Our panels not only improve sound quality but also enhance the aesthetic appeal of any recording studio.