Aluminium Profiles for Windows and Doors Market Trends, Growth, and Opportunities

Modern city skyline illustrating the impact of aluminium profiles in sustainable architecture (AI-generated)

Modern city skyline illustrating the impact of aluminium profiles in sustainable architecture (AI-generated)

Introduction: The Rising Demand for Aluminium Profiles in Windows and Doors

As cities grow and skyscrapers reach for the clouds, the demand for aluminium profiles in windows and doors is soaring like never before. This surge is largely fueled by rapid urbanization and a booming construction industry. Imagine a bustling city skyline—each building a testament to modern architecture and energy efficiency. Aluminium profiles play a crucial role in this transformation, offering strength, flexibility, and sustainability.

One of the key drivers behind this trend is the global shift towards energy-efficient building materials. Homeowners and builders alike are increasingly opting for solutions that not only look good but also help reduce energy consumption. Aluminium profiles fit the bill perfectly, thanks to their excellent thermal performance and ability to support innovative design. In fact, the market for these profiles is projected to grow significantly, with a forecast reaching billions of dollars in the coming years. This isn't just a passing trend; it's a robust market evolution.

Consider the bustling cities of Asia-Pacific, where the demand for aluminium profiles is particularly strong. According to IndustryARC, this region holds a substantial share of the market, driven by the need for new buildings and infrastructure. These profiles are not just about aesthetics; they're about creating sustainable environments in a world that's increasingly conscious of its carbon footprint.

In summary, the aluminium profiles for windows and doors market is on a promising trajectory. With urban landscapes expanding and the call for eco-friendly materials growing louder, these profiles are set to become indispensable in modern construction. As we delve deeper into this topic, we'll explore the types of profiles available and their applications, setting the stage for a comprehensive understanding of this dynamic market.

Different types of aluminium profiles used in windows and doors (AI-generated)

Different types of aluminium profiles used in windows and doors (AI-generated)

Types of Aluminium Profiles for Windows and Doors

When it comes to choosing the right aluminium profile for your windows and doors, the options are as varied as the architectural styles they complement. Let's dive into the different types of aluminium window profiles and door profiles, each offering unique advantages.

Flat Window Profiles

Flat window profiles are like the little black dress of the architectural world—simple, versatile, and always in style. These profiles offer a sleek, modern look that suits contemporary designs beautifully. They provide a clean line finish, which is perfect for minimalist aesthetics. Imagine a chic apartment with large windows that let in ample natural light. Flat profiles ensure the window remains the star of the show, without any unnecessary distractions.

Sliding Window Profiles

Sliding window profiles are a fantastic choice for spaces where you want to maximize light and air flow without sacrificing space. Think of them as the Swiss Army knife of window designs. These profiles allow for large glass panels that slide horizontally, making them ideal for areas with panoramic views. They're perfect for homes with long walls or places where traditional windows might take up too much room. Plus, they're a breeze to maintain—just a quick slide to open or close, and you're set.

Door Profiles

Aluminium door profiles offer a robust solution for both interior and exterior doors. These profiles are known for their durability and resistance to the elements, making them a popular choice for front doors and patio entrances. Picture a bustling family home where durability meets design. Aluminium door profiles can withstand the daily hustle and bustle while maintaining their sleek appearance.

One of the standout features of these profiles is their ability to accommodate various glass thicknesses and security features. This adaptability makes them suitable for different building requirements, from residential homes to commercial spaces. Whether you're going for a traditional look or something more avant-garde, there's an aluminium profile to match your vision.

In conclusion, the types of aluminium profiles available for windows and doors are as diverse as the architectural styles they enhance. From flat window profiles that offer understated elegance to sliding window profiles that maximize space and light, each type brings its own set of benefits. As we continue our exploration, we'll look at the market size and growth projections for these profiles, giving you a clearer picture of their role in modern construction.

Market Size and Growth Projections

The aluminium profiles for windows and doors market is on an upward trajectory, much like a sprinter nearing the finish line. The global market size was valued at $55.8 billion in 2021 and is projected to reach $82.1 billion by 2031, growing at a steady CAGR of 3.8% during this period, according to Allied Market Research. This impressive growth is driven by several key factors that are reshaping the construction landscape.

Urbanization is at the forefront of this expansion. As cities expand and populations increase, the demand for new residential and commercial buildings is rising. This trend is particularly noticeable in regions like Asia-Pacific, where urban development is booming. In countries such as China and India, government initiatives like 'Housing for All' are fueling the construction of new buildings, thereby increasing the demand for aluminium profiles.

Renovation activities also play a significant role in boosting market growth. As older buildings undergo refurbishment to improve energy efficiency, aluminium profiles are often the material of choice. Their lightweight and durable nature make them ideal for retrofitting projects, where minimizing structural load is crucial.

Moreover, the shift towards sustainable building materials is a game-changer. Aluminium is highly recyclable, and its use in construction supports eco-friendly practices. As builders and architects seek to reduce the carbon footprint of buildings, aluminium profiles offer an attractive solution. They not only enhance energy efficiency but also contribute to green building certifications.

Looking ahead, the aluminium profiles market is poised for continued growth. With the construction industry embracing sustainable materials and urbanization showing no signs of slowing down, the demand for these versatile profiles is set to increase. As we move forward, the focus will shift to understanding the competitive landscape and market dynamics that influence this thriving industry.

Key Players and Market Dynamics in Aluminium Profiles

In the bustling world of aluminium profiles for windows and doors, several key players dominate the market, each vying for a larger slice of the pie. Companies like Parker Hannifin, Norsk Hydro, and Guangdong Xingfa Aluminium lead the charge, leveraging their extensive experience and innovative strategies to stay ahead. These aluminium window profile suppliers are not just names; they are trendsetters, shaping the market dynamics with their cutting-edge technologies and customer-centric approaches.

Market dynamics in this industry are as fluid as the molten metal from which aluminium profiles are crafted. Pricing trends, for instance, are heavily influenced by raw material costs. The price of aluminium, a key component, can fluctuate due to factors like global demand, energy costs, and geopolitical tensions. This volatility requires manufacturers to be nimble, adjusting their pricing strategies to maintain competitiveness without sacrificing margins.

Technological advancements also play a pivotal role in market dynamics. Innovations in extrusion techniques and surface treatments are enhancing product quality and efficiency. For example, thermal break technologies are becoming increasingly popular, offering superior insulation and energy efficiency—traits highly sought after in today's eco-conscious market. These advancements not only improve the profiles but also open new avenues for application in various architectural styles.

Moreover, the competitive landscape is shaped by strategic alliances and acquisitions. Companies are constantly seeking partnerships to expand their reach and capabilities. For instance, collaborations with local distributors can provide a foothold in emerging markets, where demand for aluminium profiles is on the rise due to rapid urbanization and infrastructure development.

As we explore these dynamics, it's crucial to consider the role of specialized manufacturers like Suqian Sunmay Aluminium Company Limited. With their expertise in crafting high-quality aluminium profiles and a commitment to innovation, they exemplify the forward-thinking approach needed to thrive in this competitive arena. Their focus on customer satisfaction and adherence to international standards positions them as a preferred partner for businesses looking to leverage the benefits of aluminium profiles in their projects.

In conclusion, the aluminium profiles for windows and doors market is a dynamic and competitive space, driven by major players and evolving market dynamics. As we transition to the next section, we'll delve into the technological advancements that are reshaping the manufacturing processes of these essential building components.

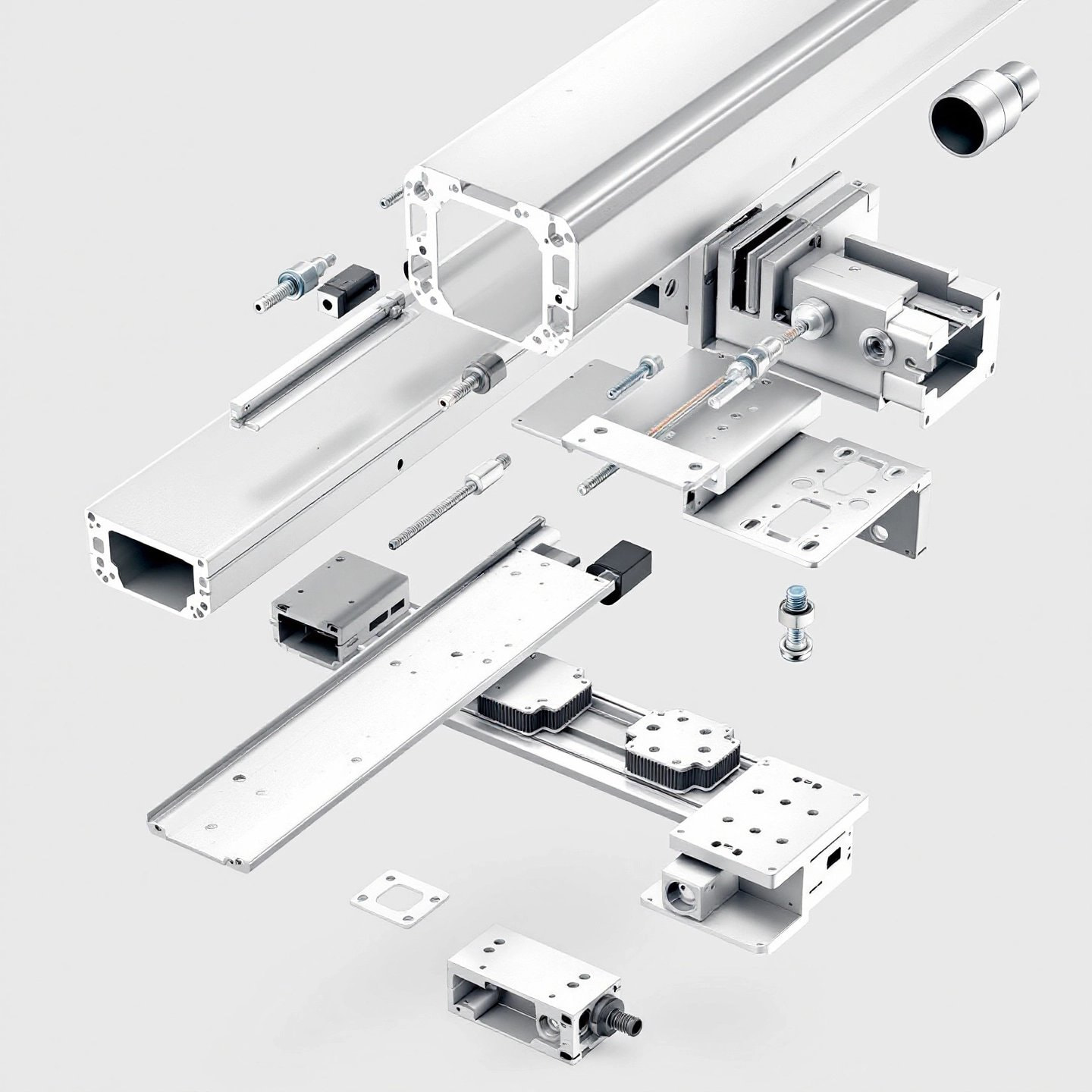

Advanced manufacturing technologies in aluminium profile production (AI-generated)

Advanced manufacturing technologies in aluminium profile production (AI-generated)

Technological Advancements in Aluminium Profile Manufacturing

In the world of aluminium profiles for windows and doors, innovation is like the secret ingredient in a top chef's recipe—it's what makes everything come together beautifully. The latest advancements in aluminium profile manufacturing technology are transforming the industry, making products more efficient, durable, and adaptable to various architectural demands.

Extrusion Techniques: A Leap Forward

Extrusion is the heart of aluminium profile manufacturing, and recent innovations are pushing its boundaries. For instance, 3D printing is now used to create complex extrusion dies, allowing for intricate designs that were once deemed impossible. This leap in technology not only cuts down on production time but also opens up a world of design possibilities, from futuristic skyscrapers to sleek residential homes.

Hot extrusion is another game-changer, allowing aluminium to be extruded at higher temperatures. This process results in profiles with thinner walls and more complex shapes, enhancing both strength and flexibility. Imagine being able to mold aluminium as easily as clay—hot extrusion brings us a step closer to that reality.

Surface Treatments: Enhancing Durability and Aesthetics

Surface treatments have evolved to offer more than just a pretty finish. Advanced anodizing and powder coating techniques now provide enhanced resistance to corrosion and wear, ensuring that aluminium profiles can withstand harsh environmental conditions. Whether it's the salty air of coastal regions or the relentless sun of desert climates, these treatments help maintain the integrity and appearance of aluminium profiles.

Thermal Break Technologies: Boosting Energy Efficiency

Thermal break aluminium profiles are like the cozy sweater your house wears to keep warm. They incorporate materials with low thermal conductivity to prevent heat transfer through the metal frame, significantly improving energy efficiency. According to IQ Glass UK, these systems are essential for meeting modern building regulations and ensuring comfort in varying climates.

Imagine a home where the windows and doors play a crucial role in regulating temperature, reducing the need for excessive heating or cooling. Thermal break technologies make this possible, contributing to both energy savings and environmental sustainability.

In summary, the advancements in aluminium profile manufacturing technology are not just about keeping up with trends—they're about setting new standards for quality and efficiency. As we continue our journey through the aluminium profiles market, we'll next explore the sustainability and environmental considerations that are driving further innovations in this field.

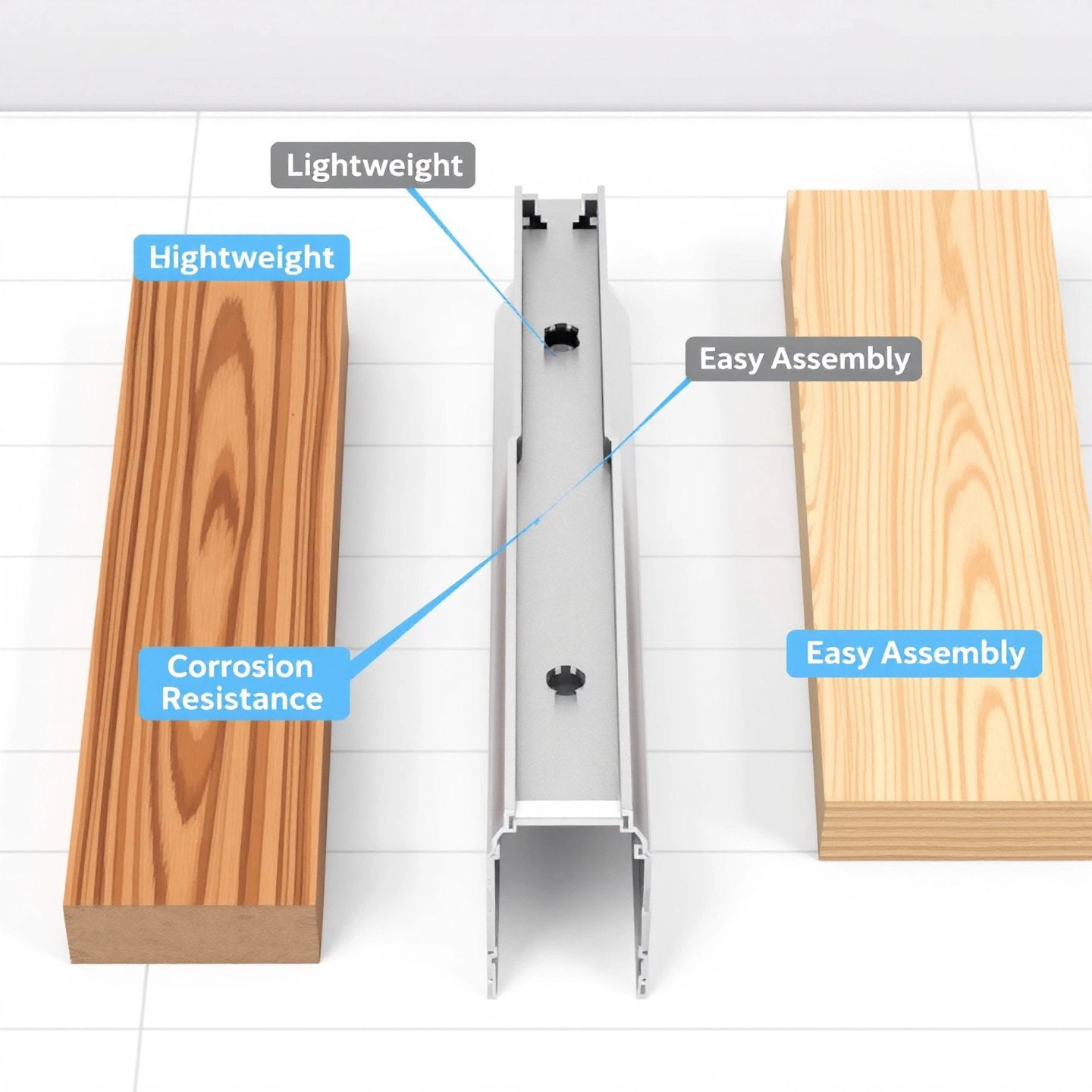

Sustainability and Environmental Considerations in Aluminium Profiles

In today's eco-conscious world, sustainability isn't just a buzzword; it's a necessity. Aluminium profiles for windows and doors are at the forefront of this green revolution. Why? Because aluminium is not only durable but also 100% recyclable, making it an environmentally friendly choice for modern construction. Imagine using the same piece of aluminium over and over again without losing quality—it's like having an endless supply of building materials.

The recyclability of aluminium is a game-changer. According to Profils Systemes, recycling aluminium saves up to 95% of the energy needed to produce new aluminium from raw materials. This energy efficiency doesn't just save resources; it also reduces greenhouse gas emissions, making aluminium profiles a key player in sustainable building practices.

Moreover, modern aluminium profiles are designed with energy efficiency in mind. They often feature thermal breaks, which help reduce heat transfer, keeping homes warmer in the winter and cooler in the summer. This not only boosts comfort but also cuts down on energy bills, making these profiles a win-win for both the environment and your wallet.

Aluminium profiles also play a pivotal role in achieving green building certifications. Many certification programs, like LEED (Leadership in Energy and Environmental Design), emphasize the use of sustainable materials. Aluminium's recyclability and energy-efficient properties make it an ideal candidate for such certifications, helping builders and architects meet strict environmental standards.

Manufacturers are stepping up their game by adopting eco-friendly practices in production and design. From using recycled materials to implementing energy-efficient manufacturing processes, the industry is making strides toward a more sustainable future. For instance, some companies are exploring ways to minimize waste during production, ensuring that every piece of aluminium is utilized to its fullest potential.

In conclusion, the sustainability and environmental considerations of aluminium profiles are reshaping the windows and doors market. As we look to the future, these eco-friendly materials will continue to play a crucial role in creating buildings that are not only beautiful but also kind to our planet. Up next, we'll dive into regional market analysis and opportunities, exploring how different areas are embracing these sustainable solutions.

Regional analysis of the aluminium profiles market (AI-generated)

Regional Market Analysis and Opportunities for Aluminium Profiles

When it comes to the aluminium profiles for windows and doors market, regional dynamics play a significant role in shaping growth and opportunities. Let's embark on a journey across key regions—North America, Europe, Asia-Pacific, and emerging markets—to understand how each is embracing these versatile profiles.

North America: A Stronghold of Innovation

North America stands tall in the global aluminium window profile market, with the U.S. leading the charge. The region's well-established construction and transportation sectors are driving demand, supported by the North American Free Trade Agreement (NAFTA) which facilitates robust trade across borders. Major manufacturers have strategically positioned themselves across various states to cater to the widespread demand from builders and fabricators. The focus here is on innovative solutions that meet stringent building regulations and energy efficiency standards, making it a fertile ground for aluminium profile growth.

Europe: Balancing Tradition and Sustainability

Europe is a fascinating blend of historic architecture and modern sustainability goals. The region's commitment to reducing carbon emissions aligns perfectly with the benefits of aluminium profiles. Countries like Germany and the UK are at the forefront, leveraging aluminium's recyclability and energy-efficient properties to meet ambitious environmental targets. The European market is also influenced by stringent building codes that favor sustainable materials, providing a steady demand for aluminium profiles in both new constructions and renovation projects.

Asia-Pacific: The Powerhouse of Growth

Asia-Pacific is the fastest-growing region in the aluminium profiles market, driven by rapid urbanization and industrialization. China, with its large-scale manufacturing capabilities and supportive government policies, leads the pack. The region's growth is further bolstered by initiatives like India's 'Housing for All' and infrastructure development in Southeast Asia. These factors, combined with relatively lower import duties, make Asia-Pacific an attractive destination for aluminium profile manufacturers looking to expand their footprint.

Emerging Markets: New Frontiers

Emerging markets in Latin America and Africa present untapped opportunities for the aluminium profiles market. Economic growth and increasing urbanization are driving the demand for modern infrastructure, where aluminium profiles can play a pivotal role. These regions are gradually adopting sustainable building practices, creating a promising outlook for future market expansion.

In conclusion, each region offers unique opportunities and challenges in the aluminium profiles for windows and doors market. From North America's innovation-driven demand to Asia-Pacific's rapid growth, the global landscape is ripe with potential. As we continue to explore this dynamic market, the focus will shift to future trends and innovations that will shape the industry's trajectory.

Future Trends and Innovations in Aluminium Profiles

The aluminium profiles for windows and doors market is on the brink of a technological renaissance. Imagine windows that not only let in light but also adjust their tint based on the sun's intensity, or doors that recognize your fingerprint and greet you with a warm welcome. These aren't just sci-fi fantasies anymore; they're rapidly becoming reality, thanks to cutting-edge innovations.

Smart Windows: The Future of Aluminium Window Profiles

Smart windows are revolutionizing how we interact with our living spaces. They use electrochromic technology to change their transparency, allowing homeowners to control light and heat with a simple switch or even automatically. This feature not only enhances comfort but also contributes significantly to energy savings by reducing the need for artificial lighting and climate control. For instance, a family in Arizona might enjoy cooler summers indoors without cranking up the air conditioning, thanks to these intelligent windows.

Self-Cleaning Surfaces: A New Era of Maintenance-Free Living

Cleaning windows is often a chore, but what if they could clean themselves? Enter self-cleaning surfaces. These glass panes are coated with a special layer that breaks down dirt and grime when exposed to sunlight, making rainwater wash them away effortlessly. Think of it as having a personal cleaning service built right into your windows, freeing up your weekends for more enjoyable activities.

Advanced Insulation Techniques: Keeping Comfort in and Energy Bills Down

Advanced insulation techniques are pushing the boundaries of what's possible with aluminium profiles. Thermal break technology, for instance, is improving energy efficiency by minimizing heat transfer through window and door frames. This innovation is akin to wrapping your home in a cozy blanket, maintaining a stable indoor temperature regardless of the weather outside. Such advancements are particularly beneficial in regions with extreme climates, where maintaining energy efficiency is crucial.

These innovations are not just enhancing the functionality of windows and doors; they're also influencing consumer preferences. As more people become aware of the benefits these technologies offer, the demand for innovative aluminium door designs and smart window solutions is expected to rise. This shift is paving the way for a future where homes are not just places to live but smart environments that adapt to our needs.

In conclusion, the future of aluminium profiles for windows and doors is bright and full of potential. With smart technologies and innovative designs leading the charge, the market is set to evolve in exciting ways. As we move forward, it's essential to stay informed about these trends and consider how they can enhance both residential and commercial spaces. Up next, we'll delve into the conclusion, summarizing the key takeaways and highlighting the role of quality and innovation in shaping the future of this dynamic market.

Conclusion: Embracing Quality and Innovation in Aluminium Profiles

As we wrap up our exploration of the aluminium profiles for windows and doors market, it's clear that this industry is not just about frames and panels—it's about shaping the future of modern construction. We've journeyed through the types of profiles available, delved into market growth, and examined the technological advancements driving innovation. The takeaway? Aluminium profiles are more than just building materials; they're the backbone of energy-efficient, sustainable architecture.

Quality, innovation, and sustainability have emerged as the cornerstones of this market's growth. High-quality aluminium profiles offer durability and aesthetic appeal, while innovations like smart windows and thermal break technologies enhance functionality and energy efficiency. These advancements not only meet the evolving needs of consumers but also align with global sustainability goals. It's like having a Swiss Army knife for your home—versatile, reliable, and indispensable.

As the demand for these profiles continues to rise, it's crucial to choose suppliers who prioritize excellence and innovation. This is where companies like Sunmay come into play. Known for their expertise in crafting top-notch aluminium profiles, they stand out as leaders in the field. Their commitment to quality and customer satisfaction makes them a go-to choice for anyone looking to enhance their building projects with the best aluminium profiles for windows and doors.

In conclusion, the future of the aluminium profiles market is bright, fueled by a commitment to quality and innovation. Whether you're an architect, builder, or homeowner, considering high-quality aluminium profiles can significantly enhance your projects. As we look ahead, embracing these advancements will not only improve our living spaces but also contribute to a more sustainable world. So, why not explore the possibilities with a trusted partner like Suqian Sunmay Aluminium Company Limited? Your next project could be just a profile away from perfection.

Frequently Asked Questions

1. Which aluminium profile is best for windows?

The 6000 series, particularly grades 6061 and 6063, are preferred for windows due to their strength and versatility, ideal for various architectural applications.

2. How big is the aluminum window market?

The aluminum window market was valued at $55.8 billion in 2021 and is projected to reach $82.1 billion by 2031, driven by urbanization and sustainability trends.

3. What are the benefits of using aluminium profiles in construction?

Aluminium profiles offer durability, energy efficiency, and recyclability, making them ideal for sustainable building practices and modern architectural designs.

4. How do technological advancements impact aluminium profile manufacturing?

Innovations like 3D extrusion and thermal break technologies enhance design flexibility, energy efficiency, and product durability in aluminium profile manufacturing.

5. Why choose Suqian Sunmay Aluminium Company Limited for aluminium profiles?

Suqian Sunmay Aluminium provides high-quality, customizable aluminium profiles with advanced manufacturing techniques and eco-friendly practices, ideal for diverse applications.