Scaffolding can be considered an irreplaceable building industry cornerstone that provides a safe solid platform for workers to perform necessary tasks at great heights. Among the numerous types of scaffolding available, however, tubular scaffolding is extremely versatile, strong and durable. We will discuss different types of tubular scaffolding, its advantages, safety considerations, common uses and many such factors while choosing the accurate scaffolding collection for the project. By the end of this article, you are expected to have a solid understanding of tubular scaffolding and how to select the right scaffold type as per your needs.

Understanding Tubular Scaffolding

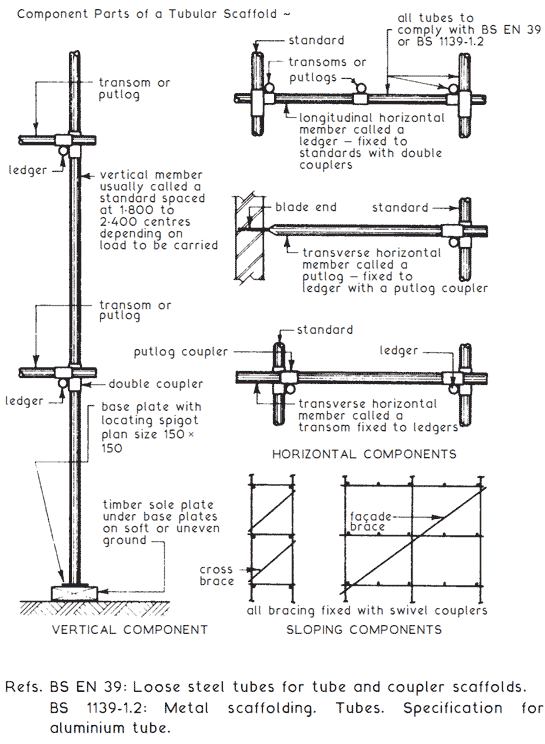

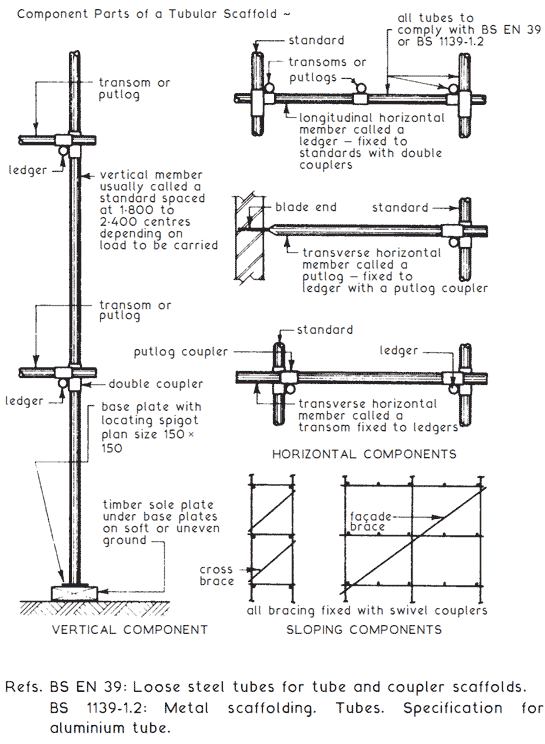

Tubular scaffolding-described as also steel scaffolding-is a type of scaffolding that is made with steel tubes and all types of couplers. The main components are the vertical tubes called standards, horizontal tubes known as ledgers, and diagonal tubes called braces which contribute to rigidity. Scaffolding is usually fitted with platforms made of wood or metal for a walking surface.

The Basic Parts Of Tubular Scaffolding:

- Standards: These are vertical tubes that transmit load to the ground. 2. Ledgers: These are the horizontal members that connect standards and provide support to the structure.

- Braces: These are inclined tubes providing additional stability to the structure.

- Base Plates: These are plates at the base of standards that help distribute the load.

- Couplers: These are tubes employed to connect adjacent tubes.

Benefits Offered By Tubular Scaffolding:

- High Load-Bearing Capacity: Steel tubes provide very good strength so they can be used in heavy-duty applications.

- Durability: Being made of steel, tubular scaffolding can withstand all weather conditions. Versatility: Tubular scaffolding is adaptable to different structures and heights.

- Re-usability: The components are reusable on multiple projects, thus making them cost-effective.

- It is safe: When assembled rightly, it can serve as a very safe working platform.

Types of Tubular Scaffolding

There are different types of tubular scaffolding that serve different purposes. The most common types include:

Tube and Clamp Scaffolding

Structure- It consists of steel tubes connected by the use of clamps.

Advantages:

Flexible and adaptable: Complex shapes can be constructed with it.

Adapted to oval and irregular shapes and angles.

Disadvantages:

A time-consuming process of assembly and disassembly;

it is, however, appropriate for craftsmen or highly skilled workers.

Applications:

It is best suited for working on irregular structures, mostly in maintenance work and those with non-standard architectural design work.

Structure: Prefabricated frames held together with cross braces.

Advantages:

Very easy and rapid to assemble.

Light and, importantly, portable.

Disadvantages:

Less flexible compared to tube and clamp scaffolding.

Limited to simple structures and low-rise buildings.

Applications:

Suitable for simple structures, residential construction, and low-rise buildings.

Structure: Uses standardized components like vertical standards, horizontal ledgers, and diagonal braces.

Advantages:

Fast assembly and high load capacity.

Modular design allows for easy customization.

Disadvantages:

The modus operandi constitutes higher initial cost compared to other varieties.

It requires specialized components.

Applications:

A great use in large construction projects, skyscrapers, industrial settings.

Safety Considerations for Tubular Scaffolding

Ensuring safety when using tubular scaffolding is paramount. Here are some key safety considerations:

Inspection of Scaffolding

- Pre-Use Inspection: Inspect all components for cracks, rust, or bent tubes that may affect the performance of the scaffolding, as this will be regarded as damaged or defective.

- Regular Inspections: Periodic inspections to maintain safety should be done, especially after extreme weather conditions.

Maintenance and Inspection

- Routine Maintenance: As far as possible, regular greasing and cleaning of components to prevent rust and hoard. Store Scaffolding in a dry covered area.

- Immediate Repairs: Replace or repair any damaged or defective parts immediately; do not use compromised components.

Worker Training and Safety Guidelines

- Comprehensive Training: Ensure that every worker receives training in applicable scaffold erection, use, and fledgling safety procedures. This training involves comprehending the load limits and proper assembly techniques.

- Safety Guidelines: Make sure that safety guidelines are included and adhered to by everyone. This has greatly to do with the proper use of PPE and adherence to assembly instructions.

Fall Protection

- Guardrails and Toeboards:Install guardrails and toeboards above the scaffold to prevent falls. Ensure that they are well anchored and conform to safety standards.

- Personal Protective Equipment (PPE): Ensure that workers are essaying harnesses, gloves, and helmets. PPE should be checked regularly on account of wear and tear.

Most Common Applications Of Tubular Scaffolding

Tubular scaffolding is widely used in various applications, including:

- Building Construction: which assists in the construction and repair of residential and commercial buildings.

- Bridge Maintenance: which is employed in bridge maintenance and repairs, including painting and structural repairs.

- Shipbuilding: during construction and repairing ships for hard-to-reach access.

- Event Stages: For setting up stages and platforms for events, concerts, and exhibitions.

- Industrial Maintenance: For maintenance work in factories, power plants, and refineries.

Factors to Consider When Choosing Tubular Scaffolding

Selecting the right tubular scaffolding involves considering several factors:

Project Height and Complexity

- Height: Higher projects may require more robust scaffolding systems with additional bracing and support.

- Complexity: Complex structures may need more flexible scaffolding like tube and clamp systems.

Load Requirements

- Weight: Scaffolding must support the weight of workers, materials, and equipment. Then establish the total load and select the scaffolding with matching load capacity.

Terrain and Work Area Conditions

- Ground Conditions: Uneven or soft ground may require additional support, such as base plates or adjustable legs.

- Space Constraints: Limited space may necessitate specific scaffolding configurations, such as narrow frames or cantilevered platforms.

Scaffolding Suppliers and Safety Standards

- Reliable Suppliers: Suppliers with good reputations and customer reviews should be selected.

- Compliance: Ensure the scaffold complies with the relevant safety standards such as OSHA or EN standards.

Budget and Schedule Considerations

- Cost: Compare the cost with prospective return benefits; for a minimal channel period, scaffolding may be rented out.

- Time: The time it will take to erect and dismantle needs to be considered. Time spent if system scaffolding is used should take less, as compared to tube and clamp scaffolding.

Conclusion

Tubular scaffolding is, indeed, a multi-purpose and essential tool that offers many more advantages such as strength, durability, and flexible use. All the different paths into tubular scaffolding, their uses, and safety considerations can all help you to make informed decisions about who, what, and how to work on your project in a safe manner. Make sure you consult with professionals to have the right scaffolding system that caters to your very needs. Whether for small residential works or large industrial sites, tubular scaffolding offers them the reliability and adaptability needed for safe and successful completion of their projects. Remember, when you make the right investment in a good scaffolding system, you could increase productivity and keep your workers safe.

FAQ

Can tubular scaffolding be used for residential projects?

- Yes, tubular scaffolding is suitable for residential projects, especially frame scaffolding, which is easy to assemble and ideal for low-rise buildings like homes.

Can tubular scaffolding be rented?

- Yes, tubular scaffolding can be rented for short-term projects. Renting is a cost-effective option if you don’t need scaffolding for long-term use.

Read More

Rama Steel Tubes Share Price Today - Stocks----GROWW

Your One-Stop Solution for Industrial Needs!----INSTAGRAM